I will summarize what is written in those articles because I believe it will help a lot to understand the scenario which we have experienced in Brazil, since the beginning of our history.

Article from “Jornal do Brasil” newspaper of 03/11/1983

“Aegis lança no mercado o primeiro “chip” com tecnologia 100% nacional” – Aegis introduced in the market the first 100% national technology chip

In this article Aegis launched the first 100% national chip. They described a few of the challenges faced to reach this achievement, among then was the difficulty to import equipment. For example, in this article, the director Marzano, Wanderley, mentioned about the diffusion furnace where the wafers should be diffused. Due to the difficulties in importing (giants taxes and suppliers at that time who couldn´t deliverer in Brazil), the furnace was manufactured inside the company. It costed 25% than a new one from any manufacturer.

This is one of many challenges to build a semiconductor company in Brazil.

At that time the only semiconductor manufacturer that was operating in Brazil was Semikron, an international company, to be precise a German company.

Article from “O Globo” newspaper of 17/06/1985

“Aegis exporta componentes para Índia e Europa” – Aegis export devices to India and Europe

After operating for 15 months, Aegis exports to Australia, Italy and India and they didn’t export more just because they have a limited production capacity at that time.

According to director Mr. Marzano, they were producing around 50.000 devices per month, when the market required around 100.000 devices per month.

At that time the turnover expectation for that year was U$1,5 million.

Article from “Informática Hoje” newspaper of 30/07/1985

“O Milagre da Multiplicação de Diodos” – The diodes multiplication miracle

The Aegis growth at the beginning – the first two years- was extremely accelerated. The fab jumped from 2000 pieces manufactured per month to 50000 pieces per month.

Even to IBM at that time used Aegis product.

They produced standard, fast recovery and Schottky diodes as well rectifiers bridges.

The only competitor in Brazil was Semikron- a german company.

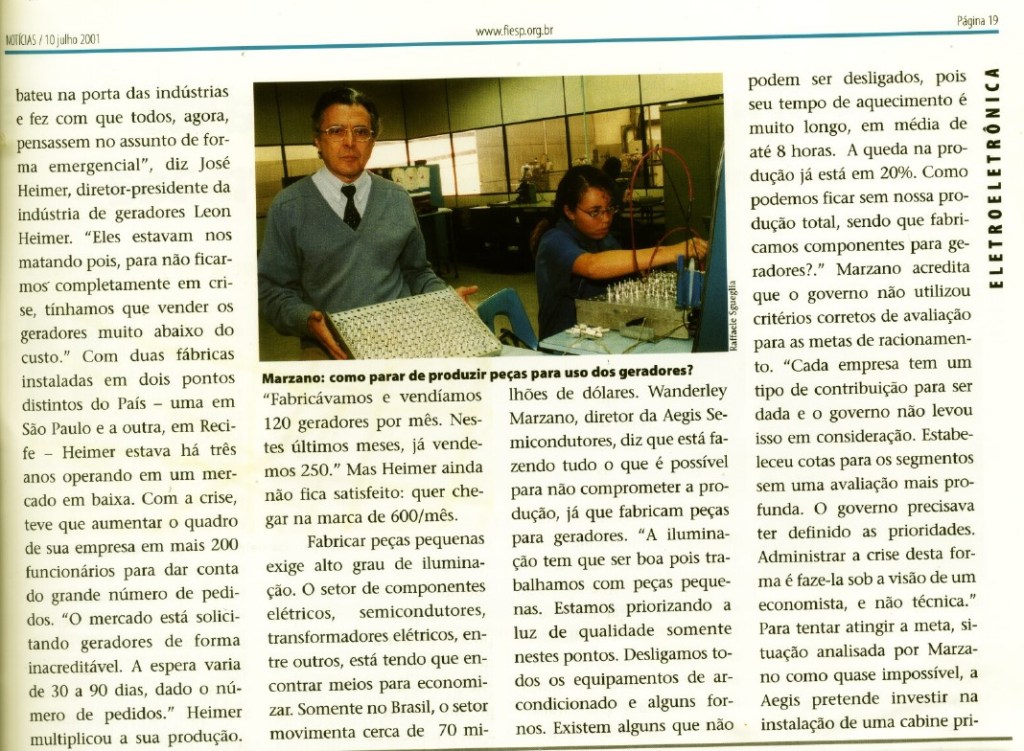

Article from “Noticias – FIESP” magazine of 10/07/2001

Article from Fiesp

In this article exists a discussion about power generator´s manufacturer, semiconductor´s manufacturer and the problem with the energy supply.

In Brazil the investment in the energy sector was never very extensive, and how it´s told in this article, even a supplier of parts – semiconductor – was harmed because of the unexpected interruption of energy. The semiconductor producer lost a lot of production capacity because of that.

Article from “O Estado de São Paulo” newspaper of 09/03/2003

“Empresa brasileira exporta semicondutores” – Brasilian company exports devices

“Even without any incentive, Aegis was exporting 30% of its production.”

The small companies have never had any credits to help to export. There is a cashflow gap between the time you buy raw materials and the payment from your goods. Something around 180 days.

For the semiconductor industry you need to deal with the fact that you have a very expensive chain of raw materials. In Brazil most of the raw materials suppliers were not national, cash flow starts problems that are very important.

That is where the government could help, but unfortunately this was not the case.

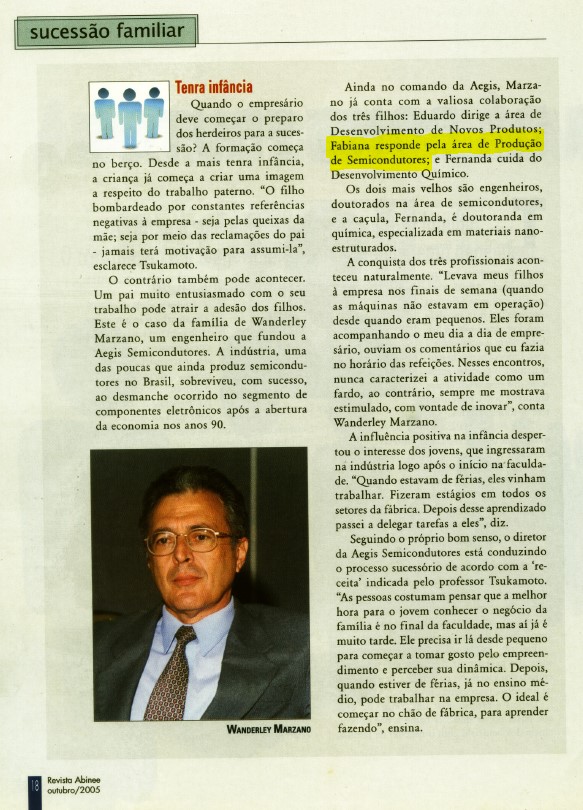

Article from “Revista da Abinee” magazine of 10/2005

“Tenra Infância” – Tender Childhood

In this article, my father tells the story about us (me, my elder brother and my younger sister) to explain why we decided, at that time, to work in his fab.

He brought us to Aegis since we were young children. That´s something I can remember of.

When we had school vacancies, not too young, we used to go to work with semiconductor process. That could explain my passion about it.