Featured Post

Who am I? Why am I creating this blog?

For those who don’t know me, my name is Fabiana, I am a Materials Engineer graduated from the Polytechnic School of the University of São Paulo (POLI-USP), where I also got my Master’s degree in Semiconductors. (Learn more in the “about” section).

Since I graduated as an engineer I started working with semiconductor high-power devices.

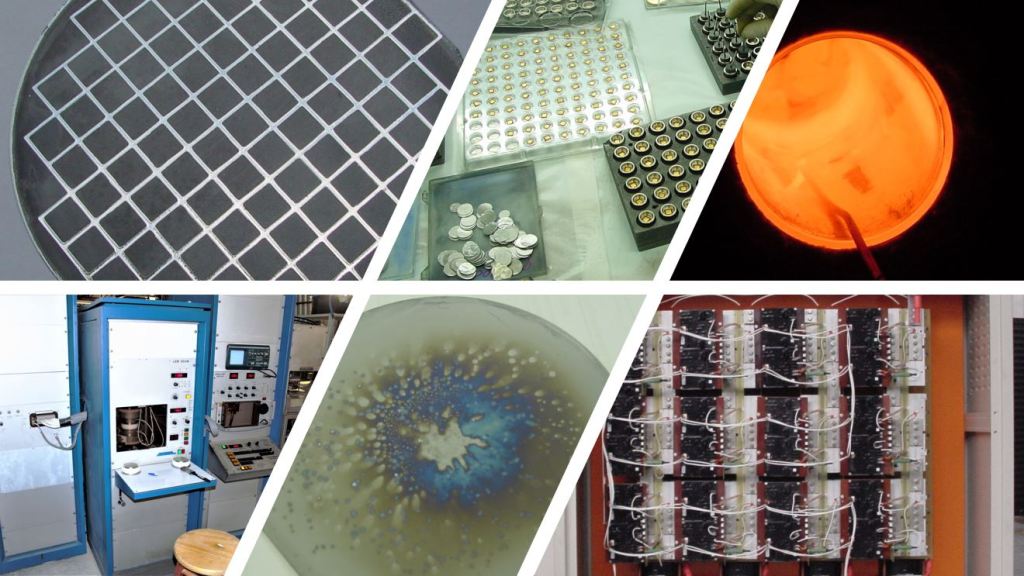

The most interesting part of my experience is that I had the opportunity to deal with an entire production line from the beginning: project, wafer, assembly, packaging, and applications.

It´s amazing to see everything integrating inside a fab! It was not easy; we faced many difficulties to surpass and developed many disruptive solutions. What guided us was to find a way to stay competitive in the semiconductor market.

When I think of semiconductor, I hardly think only on the chip, but also in assembling (casing), I always think of how to turn its use feasible and, therefore I think about all the steps of the process up to its encapsulation.

Semiconductors is one of the most complete industries in terms of processes, deals all the time with different engineering and all of them are unified in one piece, the device.

All semiconductors, through chemical and physical processes on a substrate, are translated into a device.

It´s a fantastic journey to see that happen. Let´s dig into it!

So, I invite you to see the es-semiconductor.

Welcome!

Photoresist Stripping in Semiconductor Processing

Semiconductor processing involves numerous critical steps, and one of the most important is photoresist stripping. This step requires careful attention because it ensures that the temporary masking layer used during patterning is fully removed without damaging the underlying structures and without leaving any residue behind. What is Photoresist Stripping? Photoresist stripping is the process of…

Diffusion

Let´s talk about diffusion! The diffusion is present in many semiconductor manufacturing steps. According to the semiconductor manufacturing step, the diffusion can be done with several materials and with different depths and surface concentrations. Diffusion is a two-step process: deposition and drive-in. The first one was already discussed in my previous post. Today I will…

Process: the PATH to many solutions

PROCESS, PROCESS, PROCESS …. What I like most on processes is that even if they have a common concept, it can be made in so many ways that the results can be quite unique… A process is made of several steps. Let me show that if we choose a simple process like the initial cleaning…