I believe that in our entire lives, all of us, have heard of waste or loss. How many times do we hear about food waste, water waste and of course energy losses?

We are currently experiencing a new Industrial Revolution, where we hear about Smart-Grids, IoT, AI and also Green-Tech and sustainability.

Well, this is where the loss reduction gains ground. Everything that has losses generates pollution directly or indirectly. Energy is part of this group.

We could say that energy is one of the most important pillars of this entire industrial revolution that we are experiencing. Due to that it is one of the fields that requires most innovations and optimizations. It needs to evolve to sustain all this change.

Perhaps, at this point, you may be wondering why to talk about losses and energy?

Energy and its losses are all about semiconductors. Semiconductors have a direct influence on energy consumption within the system in which it is used.

So, let us talk about the power semiconductor device. Power leads to large sums of energy consumption and losses.

During conduction, the device has a forward voltage drop in it. But what does that mean? It means that there are losses during conduction. This forward voltage drop is directly related to the power dissipated .. and power dissipated is synonymous of energy thrown away.

There is an important relationship, between the reverse voltage and the forward voltage drop. The higher the reverse voltage the larger the forward voltage drop. Here an important part of the device project is present, that is as important as the manufacturing process of that device.

The process is responsible for making this project viable or not.

Returning to the topic, energy and its losses …

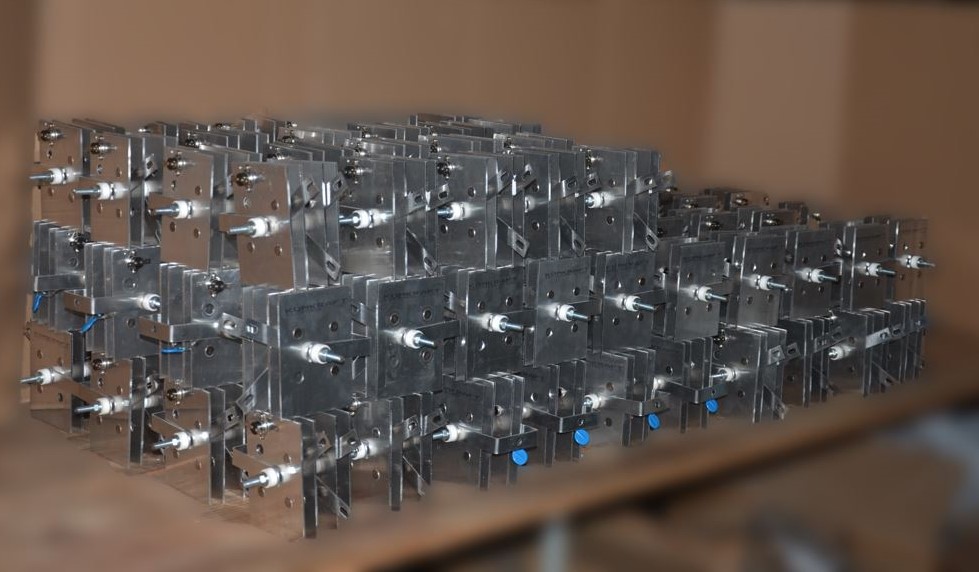

Welding machine is one of the uses of power semiconductor device widely known.

I believe it is a good example to consider losses.

Welding machine and many equipment where power semiconductor devices are used, the selection of these devices must consider those with smaller forward voltage drop. If we choose devices with better characteristics from the energy point of view (with better sizing projects and better processes), we can save at least up to 30% of energy in comparison with the situation of not working with the ideal device.

Enough, isn’t it ?!

Now, imagine if we choose a full wave three-phase rectifier bridge for 400A; that means we need to have devices with approximately 133 A each one of them. Imagine we have two stud type devices which could be used. Both of them with the same cooper base and same chip diameter, one with IFAV=130A @ 145°C, VT0=0,85V and RF=1,3mΩ ; and the other with IFAV=245A @ 145°C, VT0=0,71V and RF=0,65mΩ . In this condition, the power dissipation will be 187,98W for the first device, while for the second one it will be 131 W. The main differences between them is the resistivity of the wafer and its thickness as well as the diffusion depth.

Now we are able to observe almost 30% of energy saving using the second device.

Of course, it´s important to mention here that were considered that all the other variables that influence the power dissipation were the same for both devices, like the solder resistance, etc…

In this type of welding machine, I heard a lot that IGBT inverters are more energy efficient when compared to diode rectifiers. But how could this be possible from the point of view of the semiconductor device if the VCE of the IGBT is of the order of 2.1V against the VT0 of 0.8V for a diode? This is not possible from the point of view of devices losses.

It is worth mentioning here that the differences between the inverters and the old rectifiers is the design of the welding machines, inverters with IGBT have a much more modern designs than the old diode rectifiers.

In order to have a fair comparison, on the energy losses, between these two types of equipment, we should consider similar projects.

Here we come to interesting consideration about losses, working with semiconductor devices manufactured from an energy saving perspective, can make a huge difference.

If we start thinking about the losses and optimizations of our systems, we will undoubtedly be able to save enough energy to supply a city of more than 3 million inhabitants without much effort. Now imagine if we expand this concept all over the world ….